What

Concept description

Custom-made

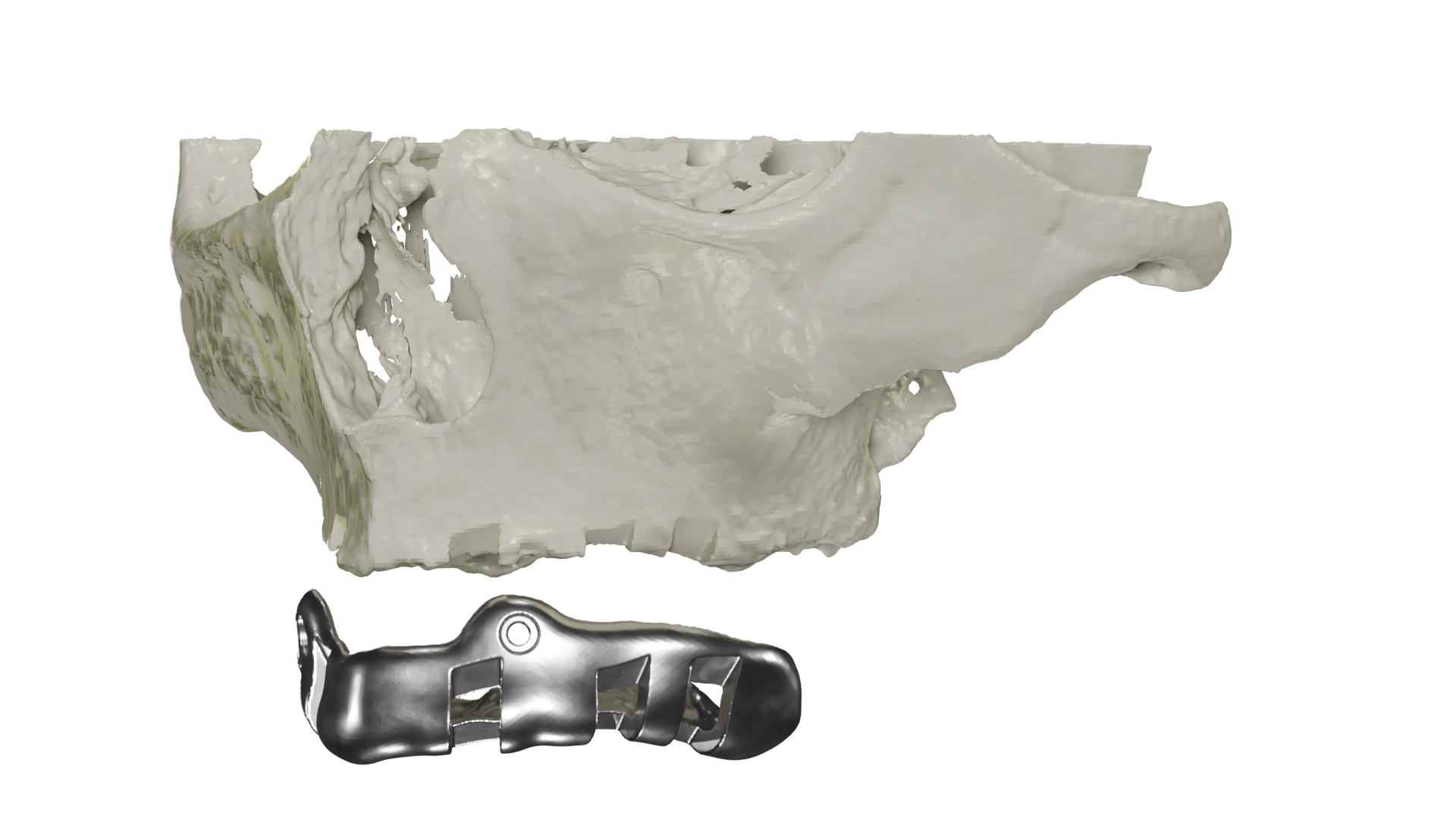

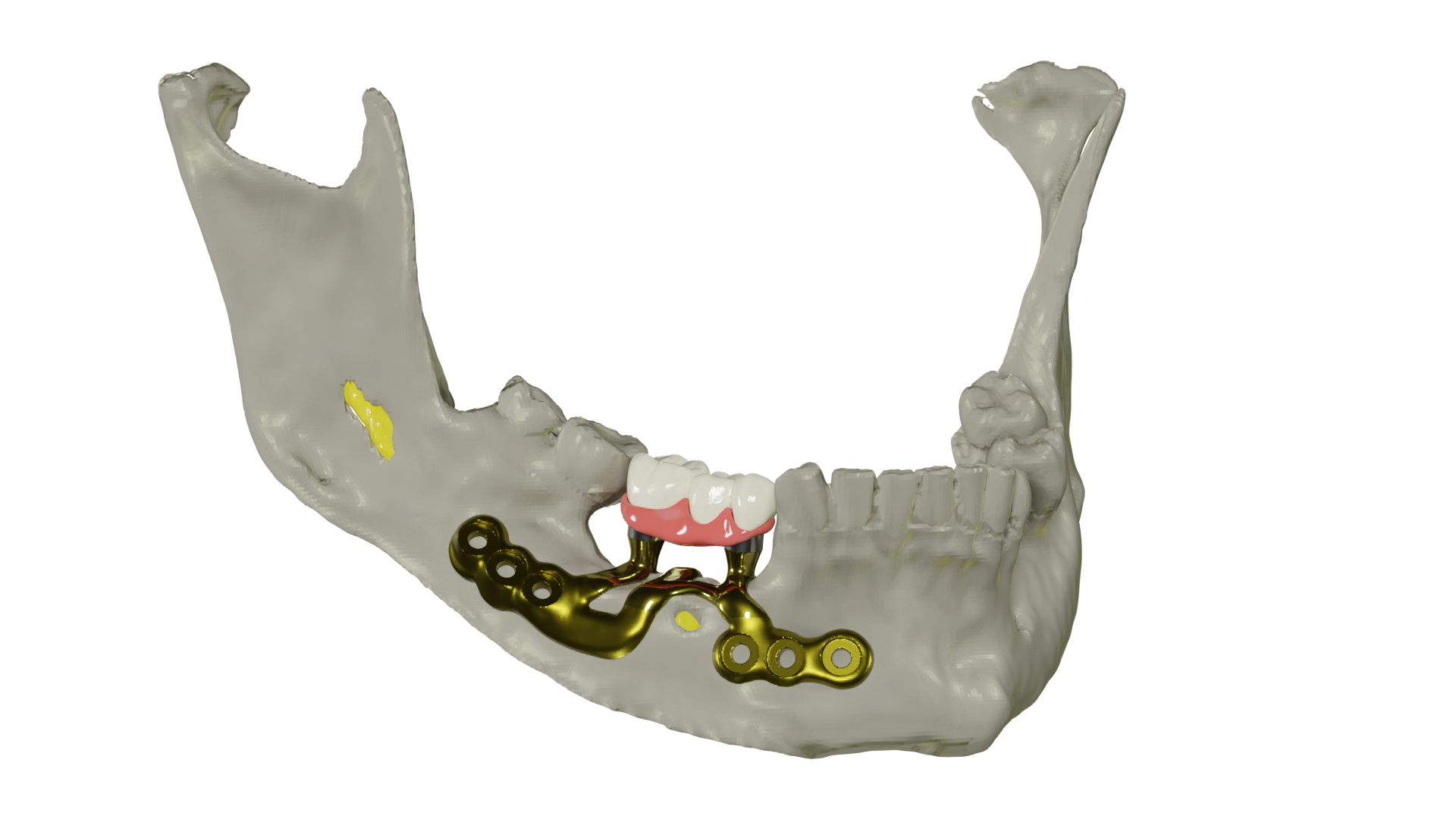

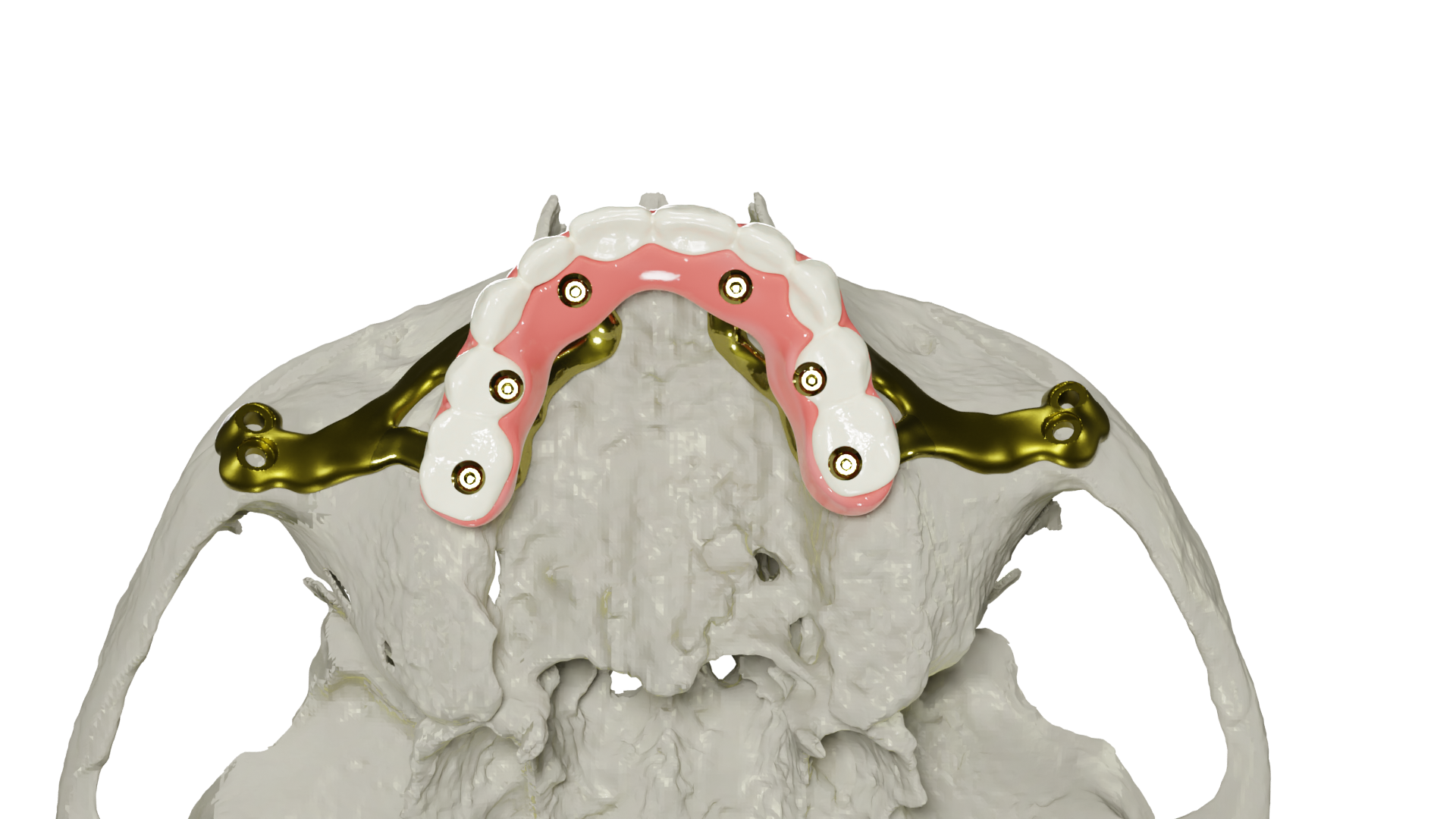

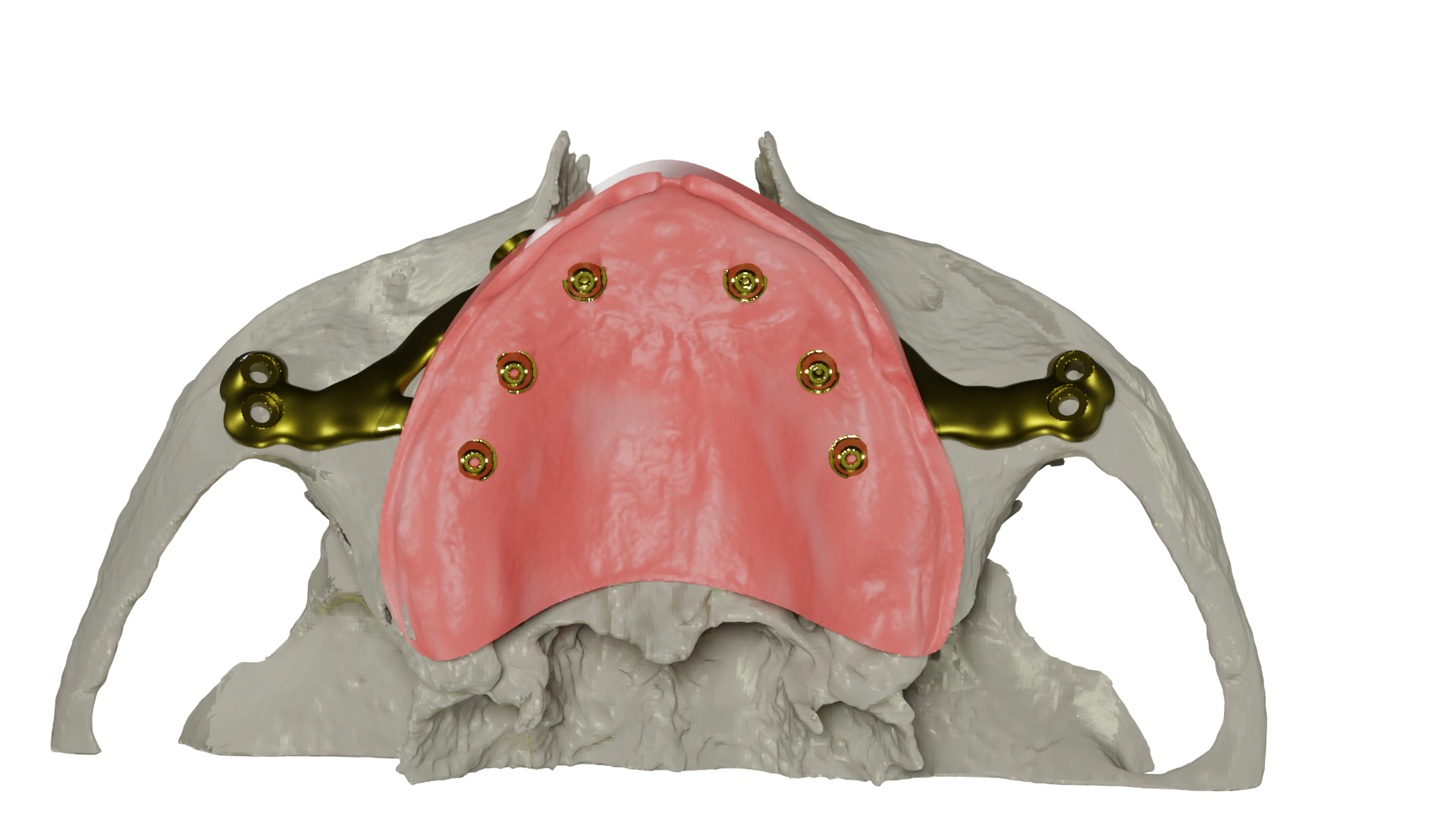

The All-on-Frame concept is fully digitally tailored to fit the anatomy of the patient and to contain the personal preferences of the surgeon. Thanks to an extensive digital toolset and 3D-printing, Trimedy can visualize, design and engineer multiple features which will benefit the quality-of-life of the treated patient.

Insufficient bone

In cases where traditional endosteal implants may require extensive bone grafting procedures, subperiosteal implants (SI) offer a practical solution. Their unique placement on the bone's surface eliminates the need for additional grafting, providing a streamlined and effective approach to dental restoration.

Minimally invasive

Balancing effectiveness, convenience, and minimal invasiveness, the All-on-Frame subperiosteal implant concept is engineered with the user in mind, offering a modern and patient-friendly approach to personalized care.

Immediate loading

Thanks to reversed engineering, the All-on-Frame always includes a screw-retained temporary prosthesis for immediate loading during the same surgery session.

Who

Clinical indications

Extreme Atrophy of maxilla and/or mandible

Cawood & Howell Class V to VIII

Trauma

The All-on-Frame concept can even be combined with facial reconstruction

Oncological patients

Implant supported dental rehabilitation after tumor resection

Partial edentulous

Ranging from a single tooth to a full upper and lower arch, the All-on-Frame is limitless

A viable alternative

The All-on-Frame concept is a viable alternative to zygomatic implants and bone grafting.

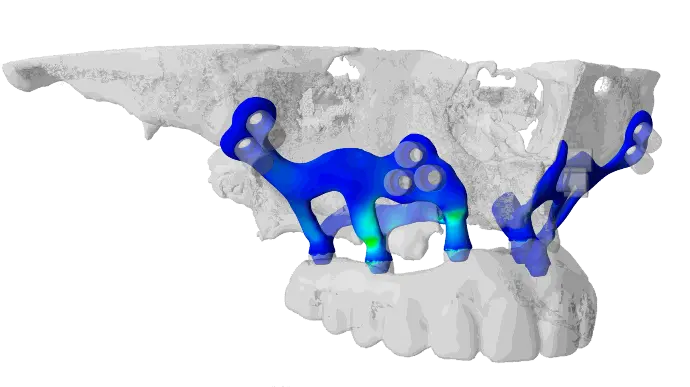

Overall design

The implants are fully adapted to the clinical situation of the patient. The overall design and the position of the transgingival connections are completely prosthetic driven, based on a dual-scan. Various parameters are taken into account, e.g.: bone density, nerves, remaining dentition, soft tissue, etc. As this is a completely patient-specific solution, the design possibilities are limitless. Always with immediate loading in mind.

Feature

Compatibility

Choose the amount and compatibility of the transgingival connections, as we offer compatibility with the major implant brands.

Feature

Temporary prosthesis

As a smile is important to all of us, we take extra care in providing a high quality temporary prosthesis with embedded titanium bar, which can be used for immediate loading until the healing period is over and a final restoration is initiated by the responsible dental clinician.

Feature

Reshaping guide

Thanks to a custom-made guide, the bone can be reshaped to remove excess bone or even to lower the arms beneath the level of the bone within the biological volume of the bone (in case of a thin biotype), to reduce excessive stress on the gingiva. This is offered as an option.

Feature

Osteosynthesis screws

You are free to choose the brand, type and number of fixation screws. Just let us know your preferences and we adapt your design as needed.

Feature

Biofunctionalization

To create an ideal and optimal interface between the 3D-printed implant and the various soft and hard tissues, the implants are treated with an extensive protocol of a combination of surface treatments:

- SLA to promote osseointegration

- High gloss polishing

- Anodization

- Lattice structure for secondary fixation

Feature

Extensive implant validation

Each implant passes various quality controls, including in silico implant design validation via finite element analysis, 3D metrology verification, model validation, etc.

General workflow

Fabrication of scan denture

Criteria for scan denture:

- 6 radiopaque scan markers

- Good stability

- Good aesthetics

- Contains no metal

Radiology (dual scan)

Perform a dual scan following the scan requirements outlined in the All-on-Frame dual scan protocol document

Ordering the All-on-Frame

To place an official order, kindly forward the DICOM files along with a written prescription to orders@trimedy.com.

Design of the All-on-Frame

Our assigned engineer will initiate the design of the All-on-Frame and provide you with the design proposal within 5* business days.

Approval of the design

To approve the design proposal, kindly send a signed copy of the document to orders@trimedy.com.

Production + delivery

Once we receive the signed design proposal, we begin the production of the All-on-Frame. The shipment is scheduled to occur 15* business days after the design proposal approval.

Surgery

The patient is treated within the hospital.

Final dental restoration

After a healing period, the patient can receive a final dental prosthesis.

The implant itself is manufactured by means of 3D-printing medical grade Ti6Al4V Grade 23 ELI. The temporary prosthesis contains a Titanium Grade 5 metal suprastructure, encapsulated in biocompatible PMMA.

Except for some additional options, the standard price includes:

- Segmentation

- Design (incl. meetings)

- All-on-Frame

- Biofunctionalization

- Temporary prosthesis

- Prosthetic screws

- Statement of Conformity

- Indicative screw length document

- Shipment

To place an official order, kindly forward the DICOM files along with a written prescription to orders@trimedy.com. This can easily be done by using e.g. WeTransfer.

Both new and existing clients can enjoy design input and advise based on

our own experience and expertise, which is included in the sales price.

We are open for brainstorming about your ideas and/or concerns, and

will gladly guide you through the whole process, based on your own need

and preference.

The All-on-Frame design involves a reverse engineering approach, necessitating the use of a reliable scan denture. During the design process, the scan denture serves as a guide for designing both the All-on-Frame and its temporary screw retained dental prosthesis.

Ideally a new teeth setup is being made, but an existing good denture can also be repurposed as a scan denture by adding at least 6 radiopaque scan markers to it.

To enhance accuracy, a radiolucent bite index can be crafted to ensure proper positioning of the denture during the (CB)CT scan.

After placing your order, you can expect a first design iteration within 5* business days. After approval of the design proposal, your All-on-Frame will be shipped within 15* business days.

*Unless specified otherwise due to circumstances

The recommended healing period is +/- 3 months following surgery. Afterwards the final prosthetic protocol can get initiated.

As the All-on-Frame concept is designed compatible with major implant systems, the prosthetic protocol does not differ with that of conventional endosteal implants.

The All-on-Frame can be made compatible with: Nobel Biocare™ Multi-unit or Straumann® SRA (4.6). This decision is made by the responsible clinician while requesting the All-on-Frame at Trimedy.

The medical images (DICOM) of the dual scan, including both the scan of the denture and the scan of the patient wearing the denture, accompanied by a written prescription.

Please contact us, if you are interested in receiving the scan protocol.

Inside the box you can find:

- The ordered implants

- The temporary prosthesis

- Prosthetic screws

- An indicative screw length document

- Statement of Conformity

Depending on the ordered options, you will also find:

- Reshaping guides

- Osteosynthesis screws

- Incision guide

- Anatomical model

One or two weeks after the surgery, a general check-up with the surgeon is advised. Two weeks later, a consult with the dentist is advised, to remove the temporary prosthesis and to clean around the transgingival posts. After two to three months, the final restoration protocol can be initiated. Preferably, a bi-annually check-up with the treating dental clinician is advised.

The implants are delivered company-clean, and are to be cleaned and sterilized using the standardized steam sterilization protocol of your hospital.

Please contact us, if you are interested in receiving the sterilization guidelines.

You can contact us via the contact page, e-mail or by calling the following phone number: +323/369.57.90.